Ampere launches ‘Cell-to-Pack’ technology, a world first for pouch-type cells.

London, July 02 2024 , (Oilandgaspress) ––– Ampere, the European specialist in smart electric vehicles, announces the expansion of its battery offering, by integrating LFP (Lithium Iron Phosphate) technology alongside NMC (Nickel Manganese Cobalt), currently used by Renault Group.

This decision is an effective and innovative response to market volatility and changing technologies.

Ampere has worked hand in hand with its suppliers LG Energy Solution and CATL to set up an integrated value chain on the European continent, in order to ensure increased competitiveness of LFP technology for its vehicles manufactured in Europe. These two partners will supply the LFP batteries that will equip several models of the Renault and Alpine ranges, and will cover the needs for this technology until 2030.

At the same time, Ampere teams have led the development of a ‘Cell-to-Pack’ technology with LG Energy Solution. This major innovation, a world first for “pouch” type batteries, makes it possible to increase the autonomy of vehicles equipped with LFP chemistry by integrating more cells, and therefore on-board energy, in a given space [1] . ‘Cell-to-Pack’ technology is also a vector for reducing the cost of the battery.

The integration of LFP and Cell-to-Pack technologies enables Ampere to reduce the cost of batteries on its vehicles by around 20% from early 2026.

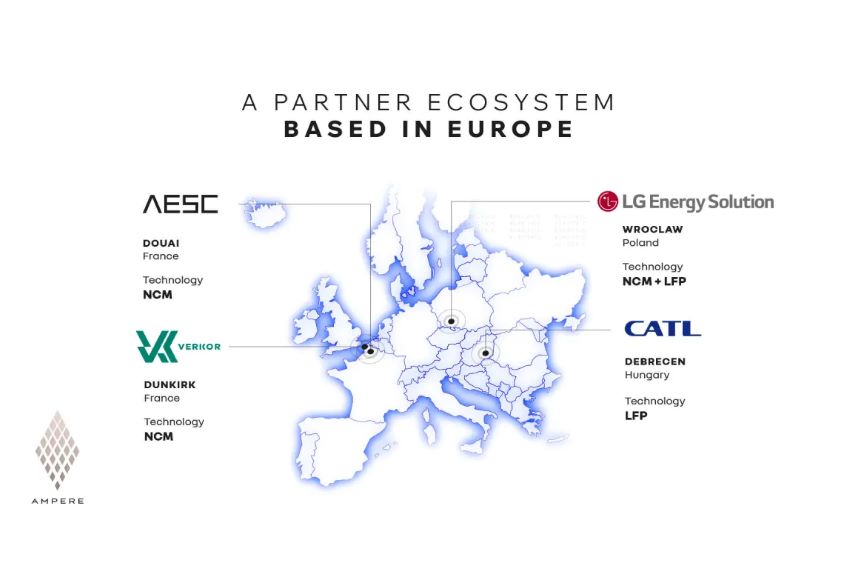

With four leading battery partners, Ampere is accelerating in a constantly changing environment, and demonstrating the effectiveness of its open approach, with the best in their field:

- AESC established at its ElectriCity site in Douai (France), for NMC batteries

- CATL for LFP technology, from its factory in Hungary

- LGES established in Poland for both technologies: NMC and LFP

- Verkor for NMC technology from its gigafactory in Dunkirk (France)

The batteries are assembled at Ampere ElectriCity (Hauts-de-France), in the battery workshop of the Douai factory.

The progress made in recent years on LFP technology and the development of the value chain in Europe now make it a real alternative to NMC. Although less energy dense than NMC, it is perfectly suited to certain uses and in particular to small and medium-sized cars. Less expensive, it is becoming an important component of the economic equation for affordable electric vehicles and their democratization in Europe.

These technologies will be implemented in vehicles in record time: the first models will be equipped with LFP batteries from the beginning of 2026.

“In a highly competitive and constantly changing environment, our battery strategy is proof of the effectiveness of Ampere’s open and horizontal approach, with the best partners, ensuring intelligent capital allocation, flexibility and speed of execution. This plan contributes to Ampere’s roadmap to reduce its costs by 40% by the next generation of vehicles,” said Josep Maria Recasens, Ampere’s COO.

“The work carried out with LG Energy Solution has allowed us to localize the entire value chain around LFP technology in Europe and to significantly increase its competitiveness, including with ‘Cell-to-Pack’. Innovation in batteries is permanent, and we are working very early on – in particular with our Battery Cell Innovation Laboratory which will open in Lardy in 2025 – in order to engage our partners very early with us on the major transformations to come” indicated Philippe Brunet, Director of EV and mechanical engineering, Ampere.