Baker Hughes & C3 AI Release BHC3 Production Schedule Optimization

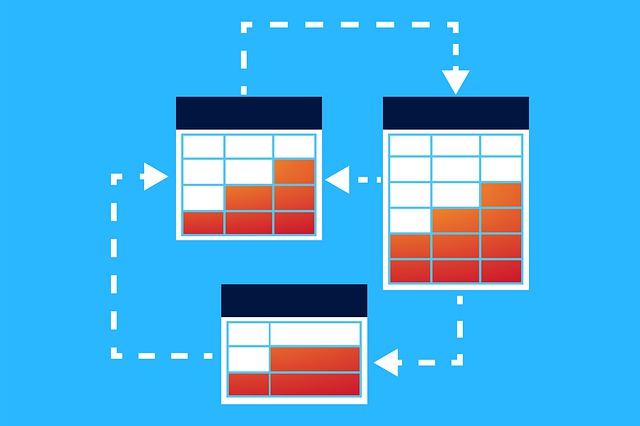

Baker Hughes (NYSE: BKR) and C3 AI (NYSE: AI) have announced the launch of BHC3™ Production Schedule Optimization (PSO), an enterprise AI application for industrial demand planning and manufacturing production scheduling. The application improves supply chain and delivery performance for highly engineered products while minimizing manufacturing costs by generating industrial customer demand predictions and optimal production schedules using a holistic view of buyer activity, supply chain materials, and manufacturing and distribution operations.

BHC3 PSO produces accurate demand forecasts for industrial and oil and gas operations as well as defined manufacturing and distribution schedules, factoring in dynamic market conditions, operational constraints, and the inherent uncertainty associated with these operations. BHC3 PSO also generates actionable insights for buyers, sellers, inventory analysts and production schedulers to make near real-time adjustments to production schedules for industrial and oil and gas operations. The application is now generally available to oil and gas and manufacturing businesses globally and is the latest addition to the growing portfolio of BHC3 artificial intelligence (AI) applications from the BakerHughesC3.ai alliance.

BHC3 PSO integrates a wide range of inputs, including feedstock availability, changing market prices, priority customer orders, increasing reworks, and unplanned downtime. With the application, users can optimize goals across manufacturing and distribution activities, including inventory minimization and throughput maximization, while considering operational constraints including storage policy, asset performance, and resource availability.

BHC3 PSO has already demonstrated success with trial customers. For example, a large hydrocarbon processing company that configured BHC3 PSO for a polypropylene plant was able to optimize production schedules and reduce manufacturing costs. After a 16-week trial, the company achieved a 20% improvement in demand forecasting accuracy by generating optimal production schedules without manual adjustment and adopting machine learning models.

“We are committed to leading and advancing the digital transformation of energy operations globally. This application is the latest in a series of new AI solutions we have launched in recent months that allow customers to achieve significant cost reductions, new levels of productivity, and organizational alignment for highly engineered products and industrial plants,” said Ed Abbo, C3 AI president and CTO. “BHC3 Production Schedule Optimization supports discrete, batch, semi-batch, and continuous manufacturing processes in network and multi-stage environments, delivering cost and productivity benefits across midstream and downstream oil, gas, and chemicals operations.”

Information Source: Read Full Release ..–>

Press release by: