U.S. Company launches electric vehicle battery recycling program

Redwood Materials, is launching the most comprehensive electric vehicle battery recycling program, beginning in California, to establish efficient, safe and effective recovery pathways for end-of-life hybrid and electric vehicle battery packs. Ford Motor Company and Volvo Cars are the first automakers to directly support the program, but we will accept all lithium-ion (Li-ion) and nickel metal hydride (NiMH) batteries in the state and welcome other automakers to join us in this effort!

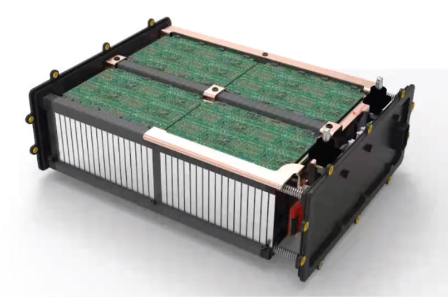

To truly make electric vehicles sustainable and affordable, we need to create pathways for end-of-life battery packs to be collected, recycled and remanufactured into new battery materials. Scaling production of EVs, increasingly from recycled materials, domestically, is the only way we can create a circular and, therefore, sustainable and secure supply chain to meet the US’ electrification plans. While the first major wave of end-of-life electric vehicles is still a few years away,

Redwood and our initial partners at Ford and Volvo are committed to creating these pathways now.

Annually, 6 GWh of lithium-ion batteries or the equivalent of 60,000 EVs, come through Redwood’s doors – most of the recycled lithium-ion batteries in North America today. We’ve been ramping our processes in preparation for the first wave of these vehicles to come off roads and we’re ready to support the battery market in identifying and creating pathways to collect battery packs.

California has always been a leader in the transition to electric transportation and, as a result, is the oldest and one of the largest electric vehicle markets on earth. When the first major wave of EVs begins to retire from roads, it will happen in California.

Information Source: Read More–>

Oil and gas, press , | Energy, Climate, Renewable, Wind, Biomass, Sustainability, Oil Price, LPG, Solar, Electric,