Eaton to Supply Breaktor® Circuit Protection Technology to Leading European-Based Vehicle Manufacturer for New EV Models

SOUTHFIELD, Mich.–(BUSINESS WIRE)–#automakers–Power management company Eaton today announced its eMobility business has received a contract to supply its Breaktor® circuit protection technology to a European vehicle manufacturer for use in multiple models of 800-volt battery electric vehicles (BEVs).

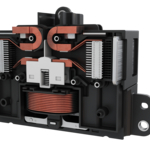

The Breaktor technology is a new advanced circuit protection solution for BEVs that combines the function of fuses, pyro switches and contactors into a single coordinated device. As electric vehicle power levels increase, the Breaktor circuit protection solution solves the ever-increasing coordination challenge between fuses and contactors while offering fast, safe and reliable protection for high-power battery and inverter systems.

“To meet EV consumer demand for longer range and faster charging, new EVs have increased power levels, which drives the need for advanced circuit protection for these high-voltage systems,” said Scott Adams, president, eMobility, Eaton. “Our Breaktor technology offers improved EV system safety and reliability with a simplified architecture. In fact, one Breaktor circuit protection unit can replace up to 15 components. We are excited to bring such a critical part of the EV system to this world-class vehicle manufacturer.”

The Breaktor circuit protection technology is an innovative solution that leverages Eaton’s industrial electrical technology and automotive expertise to deliver performance and reliability while simplifying architecture. With a less than 4-millisecond actuation for short-circuit faults up to 900 volts and 25,000 amps, the Breaktor circuit protection technology improves vehicle safety and protects components from any level of overcurrent condition more effectively than traditional circuit protection methods. The Breaktor circuit protection solution is resettable like a circuit breaker, enabling reactivation of the device following a functionality check and reducing cost for both the OEM and consumer.

“In the event of a collision, Eaton’s Breaktor circuit protection technology works in tandem with a vehicle’s safety systems,” Adams said. “It rapidly disconnects the high-voltage battery from the rest of the vehicle for protection and safety in the event of any unsafe condition.”

The Breaktor circuit protection technology provides BEV manufacturers with several additional benefits, including:

- A self-triggering device that can sense a current spike and interrupt the circuit without the need for any external sensing or triggering.

- A current-limiting device in the event of a short circuit, improving system-level protection.

- Operating independently of current direction, which allows for both charging and duty use under full electrical load.

- Availability in multiple configurations, including voltage levels and multi-pole designs.

The Breaktor circuit protection solution was designed and tested at Eaton’s advanced electrical facility in Bonn, Germany, with sub-production scheduled to begin this year in Gummersbach, Germany, and final assembly to take place in Győr, Hungary.

Eaton is an intelligent power management company dedicated to improving the quality of life and protecting the environment for people everywhere. We are guided by our commitment to do business right, to operate sustainably and to help our customers manage power ─ today and well into the future. By capitalizing on the global growth trends of electrification and digitalization, we’re accelerating the planet’s transition to renewable energy, helping to solve the world’s most urgent power management challenges, and doing what’s best for our stakeholders and all of society.

Founded in 1911, Eaton has been listed on the NYSE for nearly a century. We reported revenues of $19.6 billion in 2021 and serve customers in more than 170 countries. For more information, visit www.eaton.com. Follow us on Twitter and LinkedIn.

Contacts

Thomas Nellenbach

thomasjnellenbach@eaton.com

(216) 333-2876 (cell)