PolyCera® Awarded Second Phase of Major Lithium Extraction Project in Tibet, China

INGLEWOOD, Calif.–(BUSINESS WIRE)–#lithium–PolyCera®, a brand of PSP.US, Inc., a global leader in innovative membrane technology, is proud to announce its selection for the second phase of the Salt Lake Lithium Extraction project in Tibet, China. This expansion significantly increases the total treatment volume to over 100,000 m³/d, further establishing PolyCera®’s critical role in supporting the renewable energy industry.

Following the outstanding performance and positive operator feedback from Phase 1, where PolyCera® successfully implemented an advanced membrane system with a capacity of 1,900 m³/h, the project developers have reaffirmed their trust in PolyCera®’s innovative technology and proven expertise.

Phase 2, scheduled for delivery by June 2025, will add an additional capacity of 2,300 m³/h, enhancing the extraction of lithium—a crucial component for renewable energy storage and electric vehicles. PolyCera® will deliver the entire membrane solution, including elements, pressure vessels, and racks.

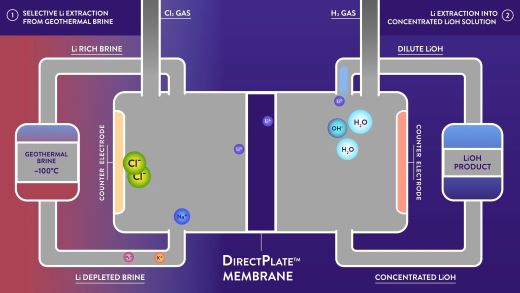

“In this project, PolyCera® Hydro-UF membrane separates freshly formed magnesium hydroxide precipitates at a concentration of over 700 mg/L and pH ~13 from lithium-containing brine without pretreatment due to its superior chemical resistance and monolith module design. Moreover, the temperature of the salt lake brine is below 40°F in winter, PolyCera membrane is operated at a lower operating pressure than that of a conventional membrane product because of its hydrophilicity and high water permeability,” said Jinwen Wang, Vice President of Product at PolyCera®.

“We are honored by this continued trust and recognition of our technology’s capabilities,” said Jianbo Wen, CEO of PolyCera®. “Winning the second phase of this project highlights PolyCera®‘s leadership in sustainable innovation, demonstrating our commitment to solving complex water and wastewater challenges globally.”

This landmark project addresses global lithium shortages, showcasing a scalable and sustainable solution to lithium extraction challenges. By integrating advanced adsorption-separation technology and photovoltaic energy, the project embodies a model of industrial efficiency and environmental responsibility.

About PolyCera®

Established in 2016, PolyCera® developed the 3rd membrane material inspired by Nobel Prize-winning research, combining ceramic durability with polymer affordability. With a global installed membrane capacity exceeding 228,000 m³ per day, PolyCera® continues to pioneer breakthroughs in water and wastewater treatment across industries including mining, oil and gas, zero liquid discharge (ZLD), and municipal water reuse.

Contacts

For media inquiries:

PolyCera® Communications

info@polycera.com

+1 424.376.3900