Sakuu Achieves New Battery Benchmark of 800 Wh/L Energy for Wide Industry Applications

The company is on track to begin shipping its SSBs produced by novel and scalable manufacturing in 2023

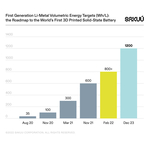

SAN JOSE, Calif.–(BUSINESS WIRE)–Sakuu (https://www.sakuu.com/), developer of the world’s first 3D printed solid-state battery, today announces the benchmark energy-density achievement of 800 Wh/L in its first-generation non-printed lithium metal battery. This marks a significant milestone on Sakuu’s roadmap to fully 3D printable solid-state batteries capable of greater than 1200 Wh/L by 2023. Until now, market-leading lithium-ion batteries, like those found in today’s top-selling electric vehicles, have functioned in a range of 500–700 Wh/L.

“The arrival of a safe, sustainable, and high-performance SSB, manufactured with a totally novel 3D printing method can solve critical supply chain and safety issues while moving beyond limitations of today’s lithium-ion batteries,” states Robert Bagheri, Founder and CEO of Sakuu. “We are on track to develop that ‘holy grail’ solid-state battery by 2023, and this first-generation benchmark is a validating accomplishment on the roadmap to significantly better batteries.”

Sakuu’s first-generation non-printed battery provides important achievements in the race for improved energy storage across broad industry sectors. Sakuu battery’s Wh/L capabilities have increased exponentially since development began in August of 2020, and with this latest benchmark test completed in February 2022, is more promising than leading commercially available batteries

In addition to the 800 Wh/L mark, the first-generation lithium-metal battery is demonstrating high energy retention at 97% after 200 cycles. The battery, while remaining dendrite-free, is expected to record 80% retention at 800 cycles once cycling has completed.

Moving ahead, Sakuu anticipates another substantial leap in energy density in its second-generation fully printed SSB, which will see sample cell deliveries begin in early 2023. The world’s first 3D printed battery, born from Sakuu’s Kavian™ platform, will offer rapid, mass-volume production of batteries in gigafactory settings, allowing for large-scale, low-cost manufacturing– capable of meeting global demand.

“We are creating a line of safe, customizable, low-cost and high-performance batteries, and manufacturing them in a completely transformative and sustainable manner to satisfy large-scale global demand,” concluded Bagheri.

About Sakuu

Headquartered in San Jose, California, USA, Sakuu is reinventing large-scale, sustainable battery technology and manufacturing. Sakuu’s breakthrough battery cells deliver best-in-class performance and safety in a recyclable format. Proprietary solid-state electrolyte and porous anode technology provide superior energy densities for maximum range and faster charge times. Sakuu’s solid-state batteries will be produced entirely through the transformative Kavian™ platform in custom or large factory settings, which enables rapid, 3D-printed, high-volume, low-cost, and sustainable production of Sakuu’s solid-state batteries– engineered to meet mass-market demand. Beyond energy, Sakuu’s Kavian™ 3D printing platform invites transformative active device manufacturing innovation in a host of other sectors, including aerospace and automotive, consumer electronics, IoT and medical.

To learn more about Sakuu, please visit www.sakuu.com

Contacts

Pal Hollywood

Sterling Communications

PHollywood@SterlingPR.com

(860) 877-9670