Top Energy/Automotive News As Reported, Friday, 24th March, 2023

London, 24 March, 2023, (Oilandgaspress): U.S. Rig Count is up 4 from last week to 758 with oil rigs up 4 to 593, gas rigs unchanged at 162 and miscellaneous rigs unchanged at 3. Canada Rig Count is down 42 from last week to 165, with oil rigs down 36 to 86, gas rigs down 6 to 79.

Crude oil prices fell on Thursday after the Federal Reserve booked a 25 basis points rate hike amid concerns surrounding the US banking sector and worry over lower oil demand.

A US city is banning new petrol stations.Lousiville, near Denver in the state of Colorado, is home to around 21,000 people and currently has five stations. A sixth was recently approved but it could be the city’s last.

The new local legislation notes that “gasoline station bans may also be seen as promoting the use of Electric Vehicles (EVs), thus, reducing vehicle emissions and encouraging low-carbon and cleaner energy options for transportation.”

It adds that the proposal for a cap on petrol stations and not a full ban is because there will still be demand while more electric vehicles are phased in.

Any new petrol stations granted an exception to the ban or those that are modified will also have to install at least two electric vehicle chargers as part of the legislation. They will also have to be at least 1000 feet (just over 300 metres) from existing ones. Petaluma, Santa Rosa in Sonoma County, California became the first city in the US to ban the building of new petrol stations. Around 60 per cent of the trips residents make here are less than 8 kilometres across mostly flat ground. Read More

As announced on 1st February, the new Board has now commenced its comprehensive strategic review of Capricorn’s business and the several potential directions for the future of the Company. Ahead of announcing the initial results of this strategic review on 27 April, Capricorn today provides an update on decisions which have been made about the Company’s exploration portfolio and cost base.

In the earliest days of the strategic review, the Board concluded Capricorn’s near-term strategic focus should be primarily on Egypt, and to farm down, monetise or exit exploration concessions outside Egypt. As a result, Capricorn will need a substantially reduced headcount in the UK and will therefore shortly enter a redundancy consultation process which is expected to result in an organisation of less than 40 people in the UK. Capricorn anticipates the majority of these changes will be made in the coming two months.

As a result of the reduced headcount, the Company will be reviewing its UK office space requirements to align to the expected size of the renewed organisation. Read More

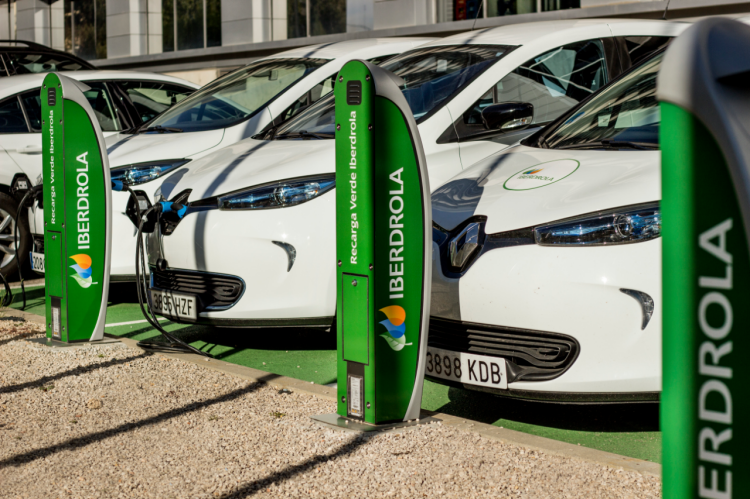

Iberdrola leads the Atmosphere consortium with the participation of Ingeteam, Inerco, ABC Compressors, IDESA and Innomerics, whose main objective will be to research new technologies associated with critical equipment in green hydrogen generation plants, covering the entire value chain, so as to enable a significant reduction in investment costs and the operation and maintenance of these plants. To validate the developments carried out in the project, the Iberdrola plant in Puertollano (Ciudad Real), one of the world’s largest hydrogen production systems using electrolysis (20 MW), will be used.The initiative, which runs from 2022 to 2025, has a total budget of 6.2 million euros earmarked entirely for research, is part of the Missions programme of the Centre for the Development of Industrial Technology (CDTI), an agency of the Ministry of Science and Innovation, and has secured funding of €4.1 million. The project represents the public-private commitment to promote a collaborative R&D&I scheme that accelerates the fulfilment of the energy transition objectives. It also highlights the need to promote a safe, efficient and clean energy for the 21st century, such as green hydrogen. The public-private commitment is satisfied with the participation of seven public research organisations (OPIs), including technology centres and universities, such as: TECNALIA, IIT Comillas, the Idonial Foundation, the Public University of Navarre (UPNA), the Andalusian Association for Research and Industrial Cooperation (AICIA), the CEIT Technology Centre Association and IDESA Technology & Research Centre.Throughout this project, research into different technologies and elements associated with green hydrogen will enable progress to be made in the decarbonisation of industry, as established as a priority objective of the Green Hydrogen Roadmap in Spain. Read More

The Chairman of Iberdrola, Ignacio Galán, assured the President of Brazil, Luiz Inácio Lula da Silva, that Iberdrola will be a loyal ally in the country’s energy transition. This was expressed during their visit to the company’s first hybrid complex in Brazil. Located in the interior of Paraíba, in the northeast of the country, the Neoenergia Renewable Energy Complex integrates wind and solar power generation for the first time in this country, thanks to the Chafariz wind farm and the Luzia photovoltaic plant. The complex has involved an investment of €630 million and will supply clean energy to 1.3 million homes.The Neonergía Renewable Complex has a capacity of 600 MW, which will prevent the emission of more than 100,000 tons of CO2 per year. The complex consists of 15 wind farms with a total of 136 wind turbines – with an installed capacity of 471.2 MW – and two solar plants of Neoenergia Luzia, with 228,000 panels and an installed capacity of 149.2 MWp. Connection to the grid is guaranteed by the substation and the transmission line, with a length of 345 kilometers.A pioneer in the country, the project stands out for the synergy between wind and solar farms, thus reinforcing Iberdrola’s commitment to the development of the Brazilian energy sector in an innovative, efficient and sustainable manner. Hybridization allows for more efficient management of the two renewable sources, cost reduction and better use of the full potential, including the transmission system. “Making projects like this a reality requires political leadership capable of establishing long-term planning, a clear energy policy and stable and encouraging regulation,” said Ignacio Galán, chairman of Iberdrola. “We started in Brazil 20 years ago and today we are more than one hundred companies operating in all segments of the Brazilian electricity sector and serve almost 40 million people with a total of 16,000 employees. Iberdrola and Neoenergia will continue to be loyal allies of Brazil”, said Galán. For this reason, the electricity company’s chairman has pledged to invest 30 billion reais – some €5.3 billion- over the next three years in the country, to continue developing new renewable and grid projects, as well as to make the most of the opportunities offered by technologies such as offshore wind power and green hydrogen. Read More

In its commitment to a more innovative and sustainable Board, Iberdrola inaugurates the Shareholder Month. It is an interactive space with four thematic rooms related to the environment, governance, social and financial aspects. Available through the corporate website, it includes, among other things, interviews, reports, and information pills.Once again, the company is a benchmark in facilitating the monitoring and participation of shareholders not only in person, but also through the main digital channels and the most convenient and useful mobile applications for shareholders. Therefore, from this area it is possible to access the Shareholders’ Meeting Participation Portal, as well as to follow the event live on 28 April. All the information on the AGM is also available and the Shareholders’ Office can be accessed. This space is completed with detailed information on Iberdrola’s art collection. Through its works, the company aims to contribute to the promotion, conservation and dissemination of heritage and the artistic ecosystem in those countries where it is present. Read More

Today Automobili Lamborghini is a world-renowned company, with over 2,000 employees and delivering 9,233 cars in 2022. However, when Ferruccio Lamborghini founded the company in 1963, he started from scratch. Over the last 60 years, Lamborghini’s headquarters where the iconic cars continue to be created has undergone upgrades, extensions and reconfigurations based on production, environmental and technological needs, but it has never lost its original core structure.

Ferruccio Lamborghini looked for a location to set up his new company and chose the land to build his new factory in Sant’Agata Bolognese, just a few kilometers from his hometown of Cento. Construction of the initial part of the factory, considered to be one of the most modern of its time, was very fast and finished in just eight months between the autumn and winter of 1963. On October 20 of the same year when Ferruccio Lamborghini invited the press to the launch of the first Lamborghini car, the 350 GTV prototype, the completed main structure of the factory was already visible in the photograph’s background.

In 1966 when the gearbox and differential also started to be manufactured in-house, the production, offices, test rooms and service workshop could be found in the 12,000 m2 covered area of the original structure. There were two production assembly lines: one for the engines and mechanical parts and the other for car assembly with ancillary machinery for parts production and vehicle tuning. The offices, spanning 260 meters and located along the front and in the center, included the president’s office and the offices of the technical and sales departments. On the right side of the building were the test rooms and on the left the customer service workshop and staff rooms. Right from the start, Lamborghini focused on the use of technologically advanced machinery, combining the artisan skills of the workers with the most advanced technology available, a value that remains at the heart of the company’s industrial vision today.

On October 18, 1968, Lamborghini announced the imminent completion of three new industrial buildings, adding 3,500 m2 of covered area. These were buildings that, as well as strengthening the production facilities, would also create a modern, well-equipped test department. The photograph accompanying this press release is now iconic given that it shows, in addition to the department under construction, a 400 GT, an Islero, an Espada and two Miura.

Production went from 67 Lamborghinis produced in 1965 to 425 in 1971, falling to 55 in 1979 due to the economic crisis of the 1970s. The 1980s marked a resumption of production, reaching 470 cars produced in 1987 together with 300 marine engines.

In 1983, Lamborghini launched the development and use of carbon fiber for the first time. The new ‘Esperienza Materiali Compositi’ Department (known as E.Co), was set up thanks to the arrival of know-how from Seattle that was developed from the first carbon fiber and Kevlar components of the Boeing 767. The first carbon fiber chassis prototype of the Countach Evoluzione was created: this was the first use of composite materials by Lamborghini and an absolute first for a project of this type for a road car.

In 1990, equipment required for research, development and testing in the field of electronic systems and new composite materials was purchased. A testing and development workshop for emission control systems was also created, allowing this process to be managed directly in-house from that point onward.

Joining the Audi group in 1998, the speed of development at Lamborghini grew exponentially, as did the number of cars produced and the number of employees. In 2000, Lamborghini produced 296 cars and employed 440 staff; in 2001, the renovation of the headquarters was completed, the first after many years, involving the construction of a new office building, a two-story museum and a new research and development area, in addition to the investment in assembly lines and canteen that were completed in August 2001 for a total of 155 million Euro. Read More

Stellantis announced it will invest over €130 million in the Eisenach Assembly Plant in Germany, producer of the Opel Grandland compact SUV, to add production of the BEV successor vehicle that will be built on the all-new STLA Medium platform. Production of the new BEV is scheduled to begin in the second half of 2024.

Adding a BEV to Eisenach’s output supports Opel’s bold commitment to a fully electric product lineup by 2028 in Europe. The Opel Grandland currently produced at Eisenach includes also plug-in hybrid variants.

“Eisenach, our most compact plant in Germany, has demonstrated a strong drive in quality improvements,” said Arnaud Deboeuf, Stellantis Chief Manufacturing Officer. “With this allocation of Stellantis’ new fully BEV platform, STLA Medium, Eisenach plant’s highly skilled workforce will continue to improve the cost and the quality of the vehicles they produce to delight our customers.”

“We have been building top-quality vehicles here in Thuringia for 31 years and improved our competitiveness continuously. We will stay on this clear path with the electric successor to the Opel Grandland,” said Florian Huettl, Opel CEO. “This decision is another important step for Opel on the way to the declared goal of being a purely electric brand in Europe by 2028.”

“At Stellantis, ‘We Win Together’ is a core value and this announcement for Eisenach demonstrates that value in action,” said Xavier Chereau, Chairman of the Opel Supervisory Board and Chief Human Resources & Transformation Officer at Stellantis. “A focus on improving quality and costs from Eisenach management and employees, combined with the input and social dialogue with the German union representatives, help define the future.”

“Thuringia is an automotive location with a great tradition that is currently making the transition to electromobility at top speed,” Thuringia Prime Minister Bodo Ramelow said. “Against this background, I am particularly pleased that Opel is playing a decisive role here and will be producing a future-proof model range in Eisenach.”

Opened in September 1992 with production of the Opel Astra, the Eisenach Assembly Plant is in the state of Thuringia, central Germany. In 2022 the plant celebrated its 30th anniversary with an Open Day event that commemorated production of 3.7 million vehicles.

The Eisenach investment is a key step in meeting the commitments of the Dare Forward 2030 strategic plan, which is led by deep emission cuts to slash CO2 in half by 2030, benchmarking 2021 metrics, and achieve carbon net zero by 2038 with single digit percentage compensation of the remaining emissions. Core targets for Dare Forward 2030 also include 100% of passenger car sales in Europe and 50% of passenger car and light-duty truck sales in the United States to be BEVs by the end of the decade; the ambition of doubling Net Revenues by 2030 (versus 2021) and sustaining double-digit Adjusted Operating Income margins throughout the decade; and the aim to become number one in customer satisfaction for products and services in every market by 2030.

Stellantis is investing more than €30 billion through 2025 in electrification and software to deliver BEVs that meet customer demands. Read More

Baker Hughes Rig Count

U.S. Rig Count is up 4 from last week to 758 with oil rigs up 4 to 593, gas rigs unchanged at 162 and miscellaneous rigs unchanged at 3.

U.S. Rig Count is up 88 rigs from last year’s count of 670 with oil rigs up 62, gas rigs up 25 and miscellaneous up 1.

The U.S. Offshore Rig Count is up 1 to 18, up 4 year-over-year.

Baker Hughes Rig Count: Canada is down 42 to 165 rigs.

Canada Rig Count is down 42 from last week to 165, with oil rigs down 36 to 86, gas rigs down 6 to 79.

| Region | Period | Rig Count | Change from Prior |

| U.S.A | 24 March 2023 | 758 | +4 |

| Canada | 24 March 2023 | 165 | -42 |

| International | February 2023 | 915 | +14 |

Electric cars are being written off for having the slightest damage to battery packs following accidents because there is no way of repairing them, according to a report by Reuters.

It said insurance companies are increasingly being left with little to no choice but to permanently take the cars off the road after minor collisions, which in turn is pushing premiums on electric vehicles (EVs) higher.

The report warns of scratched and mildly damaged battery packs ‘piling up in scrapyards in some countries’ with experts saying batteries in expensive Tesla Y SUVs have ‘zero reparability’ because they are a structural part of the car.Battery packs are the most expensive part of an EV and make up around half the total price of electric cars.

That means any damage to them will likely make the vehicle uneconomical to repair and force the hand of insurance companies to write them off.Manufacturing expert Sandy Munro, CEO of Munro & Associates in Michigan, says the Tesla Model Y has ‘zero repairability’ after a crash due to the battery pack being a structural part Read More

Eni reaffirms its commitment to the energy supply chain by making available to its suppliers a new digital and sustainability-related model – in addition to “Basket Bond – Sustainable Energy” programme -. It is designed for Eni suppliers to receive advance payments from the scheme’s financial partners.

Thanks to FinDynamic’s technology and to the collaboration with Crédit Agricole and UniCredit for financial activities, Eni’s suppliers will have an additional possibility to access credit simply and quickly, and will also obtain favorable financial terms.

By joining the Sustainable Supply Chain Finance Programme, suppliers will have the possibility to request advance payment of invoices issued to Eni through the “FinTech” digital platform, which is provided by FinDynamic, a company specialised in offering innovative solutions to optimise the management of corporate liquidity.

As the banking counterparts (funders) selected by Eni for this programme, Crédit Agricole and UniCredit have initiated the process to finalise the operational procedures.

The conditions for companies to access the programme will be linked to their commitment to sustainable development, thus combining an improvement in financial resource management with ESG performance. To this end, companies will use the functionalities of Open-es, the digital platform connecting industry, finance and trade associations and dedicated to the sustainable growth of supply chains.

With this new programme, Eni is strengthening its support strategy for companies by offering concrete tools for creating long-term value while emphasising the importance of involving the entire supply chain towards a path of sustainable growth. Read More

RWE wind farm Kaskasi, located around 35 kilometres north of the island of Heligoland, officially commenced regular operation in the presence of Robert Habeck, German Federal Minister for Economic Affairs and Climate Action. With an installed capacity of 342 megawatts (MW), Kaskasi can supply the equivalent of over 400,000 households with green electricity.

The 38 wind turbines of Kaskasi were successively commissioned over four months. Since the end of 2022, all turbines have been feeding green electricity into the grid. After all required tests were successfully completed, the wind farm is now commencing regular operation. The approval procedure for the wind farm started in spring 2019 and construction was greenlighted by the German Federal Maritime and Hydrographic Agency (Bundesamt für Seeschifffahrt und Hydrographie) at the end of 2020. The total offshore construction time was nine months, the investment costs for Kaskasi amounted to around 800 million euros. More than 100 people at RWE alone worked on implementing this large project – hand in hand with the staff from over 70 suppliers. Read More

RWE, the world’s second largest offshore wind player and largest generator of clean power in Wales, has unveiled its vision for the future of floating offshore wind in the Celtic Sea region and the opportunities it presents from new large-scale, commercial projects. Entitled “RWE’s Vision for the Celtic Sea”, the document was unveiled during day one of the Marine Energy Wales conference, in Swansea, where RWE is the Platinum Sponsor.

RWE sees floating wind technology as the next frontier in the development of the offshore wind sector, and which could potentially unlock a multi-billion pound opportunity for the broader Celtic Sea region and the UK.

Studies anticipate the first GW of floating wind to be developed in the Celtic Sea could potentially deliver around 3,000 jobs and £682 million in supply chain opportunities for Wales and the south west of England. Against this backdrop, it’s anticipated the technology could unlock a resurgence in Welsh industry, helping to decarbonise industry and transport, spur on academic innovation, and spearhead the growth of a new, highly skilled workforce.

In order to deliver these bold ambitions, investment and a broad dynamic collaboration between business, industry, academia, and Governments in Wales and Westminster are required. RWE’s vision document reaffirms the company’s commitment to helping realise economic opportunities for the benefit of communities and the supply chain, by drawing upon its extensive knowledge gained from decades of leadership in offshore wind, and its emerging status as a front-runner in floating wind. Read More

Mitsubishi Heavy Industries, Ltd. (MHI), and PT. PLN Nusantara Power, a sub-holding of Indonesia’s state-owned electricity provider PT. PLN (Persero) (PLN), have signed a Memorandum of Understanding (MoU) to commence three technical studies related to co-firing of less carbon intensive fuels at power plants owned and operated by Nusantara Power. The three studies will be conducted jointly by Nusantara Power and MHI with support from Mitsubishi Power, MHI’s power solutions brand. This MoU follows a similar agreement concluded with PLN Group company PT. PLN Indonesia Power in November 2022, and will further aid in the advancement of solutions to accelerate the decarbonization of energy systems in Indonesia Read More

| Oil and Gas Blends | Units | Oil Price $ | change |

| Crude Oil (WTI) | USD/bbl | $67.43 | Down |

| Crude Oil (Brent) | USD/bbl | $73.56 | Down |

| Bonny Light | USD/bbl | $76.37 | Up |

| Saharan Blend | USD/bbl | $75.78 | Up |

| Natural Gas | USD/MMBtu | $2.19 | — |

| OPEC basket 23/03/23 | USD/bbl | $75.88 | Up |

The U.S. Department of Energy (DOE) and Stellantis today announced the launch of the Battery Workforce Challenge, which includes a three-year collegiate engineering competition; vocational training; youth education in science, technology, engineering, and math (STEM); and career and technical education.

DOE has set a bold target to address the climate crisis and puts our nation on a path to achieve net-zero emissions, economy-wide, by 2050 for the benefit of all Americans. Key to this target goal are the design and development of advanced batteries to electrify the transportation and energy sectors and a highly skilled domestic workforce with the hands-on experience and knowledge needed for in-demand positions throughout the EV/battery industry.

Managed by Argonne National Laboratory for DOE and co-sponsored by Stellantis, this government and industry partnership will build the next generation of engineers, technicians, and workers to address the unprecedented demand for a domestic EV/Battery workforce.

“American leadership in the global battery supply chain will be based not only on our innovation, but also on our skilled workforce of engineers, designers, scientists, production workers, and technicians,” said Deputy Assistant Secretary for Sustainable Transportation and Fuels at the U.S. Department of Energy, Michael Berube. “This comprehensive workforce program will build an educational ecosystem delivering training and education for high school graduates, and vocational and transitional workers, fostering a diverse talent pipeline of trained engineers, workers and technicians who can charge North America’s battery industry forward.”

Kicking off in fall 2023, the Battery Workforce Challenge includes an advanced battery design and development student competition series that invites universities and vocational schools from across North America to design, build, test and integrate an advanced EV battery into a future Stellantis vehicle.

“With our Dare Forward 2030 strategic plan, Stellantis is taking a leadership role in decarbonization that will drive us to become an industry champion in the fight against climate change, reaching carbon net zero emissions by 2038,” said Mark Stewart, Stellantis North America Chief Operating Officer. “The Battery Workforce Challenge will help train the engineers of tomorrow and is a win-win for Stellantis and the entire battery industry as we address our nation’s toughest energy and mobility challenges by helping to build a highly skilled and productive future workforce.”

Teams will follow real-world industry milestones focused on battery design, simulation, controls development, testing, and vehicle integration and demonstration. Participants will also learn valuable project management, communications, teamwork, and problem-solving skills that will provide unparalleled educational experience and ready them for future careers throughout the battery industry. Read More

OilandGasPress Energy Newsbites and Analysis Roundup | Compiled by: OGP Staff, Segun Cole @oilandgaspress.

Disclaimer: News articles reported on OilAndGasPress are a reflection of what is published in the media. OilAndGasPress is not in a position to verify the accuracy of daily news articles. The materials provided are for informational and educational purposes only and are not intended to provide tax, legal, or investment advice.

Information posted is accurate at the time of posting, but may be superseded by subsequent press releases

Please email us your industry related news for publication info@OilAndGasPress.com

Follow us: @OilAndGasPress on Twitter |

Oil and gas press covers, Energy Monitor, Climate, Renewable, Wind, Biomass, Sustainability, Oil Price, LPG, Solar, Marine, Aviation, Fuel, Hydrogen, Electric ,EV, Gas,